Cooling Towers

We have over 35 years experience repairing, refurbishing and servicing all types of cooling towers and can provide services on all cooling tower brands.

Refurbishments

The average life expectancy of a galvanized cooling tower with proper maintenance and water treatment is 18 – 20 years, but in many cases a tower will need some type of help to achieve that goal. From small mechanical repairs to fan section replacements, sump repairs or heat transfer media replacements, CT/HX can help increase equipment life expectancy. Typical scopes of work CT/HX performs are:

- Cold Water Sump Repairs / Refurbishment / Coatings / Replacement

- Heat Transfer Wetdeck Media Cleaning / Supports / Repairs / Upgrades / Replacement

- Fan Section Repairs/Upgrades/Replacement/VFD’s

- Distribution Systems and Basins Repairs / Refurbishment / Coatings / Replacement

- Service/Safety Platforms, Ladders and Safety Railings

Cold Water Sump Coating

A great way to extend the life of the typical galvanized or Baltibond tower is to refurbish the cold water sump by grinding all surfaces back down to base metal and then installing an elastomeric waterproof membrane, which will add life and thickness to the sump panels in addition to protecting the existing metal surfaces against further corrosion, add thickness to the metal and reseal all interior sheet metal seams to protect against future potential leaks. All of our coating projects include standard 3 Year Warranty.

Wetdeck/Fill

The core of any cooling tower’s performance can almost always be tied back to the performance and condition of the heat transfer fill media. CT/HX has the experience with all of the major cooling tower manufacturers and wetdeck materials including:

- BAC

- Evapco

- Marley

- Counterflow Design

- Crossflow Design

- Top supported hanging fill

- Bottom supported bundled media packs

- PVC, Wood, Steel, Ceramic

Tower Performance

There are many scenarios that can increase the demands on your cooling towers and heat exchangers, along with many others that could affect the actual performance of the equipment. Whether the load has been increased or your equipment is aging, CT/HX can help evaluate the problem and make suggestions to solve it while also providing short term needs and long term operating budget recommendations.

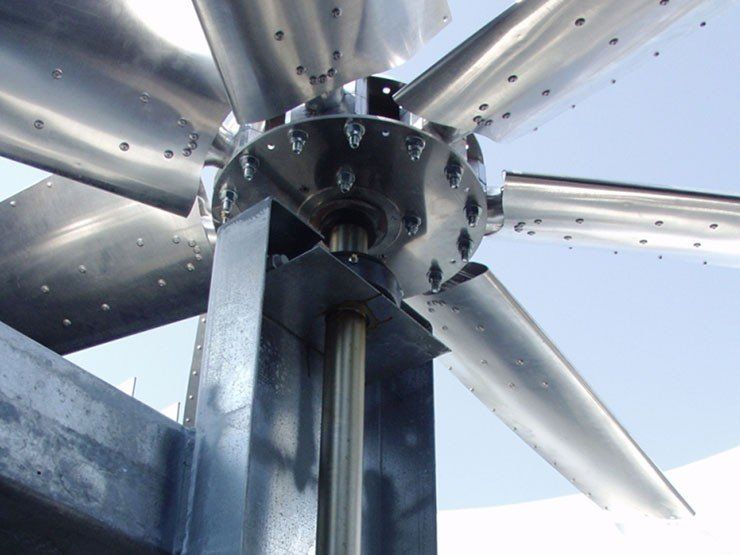

Powertrain

CT/HX has the experience with all of the major cooling tower manufacturers and fan section component design including:

- BAC

- Evapco

- Marley

- Delta

- Protec

- Counterflow Design

- Crossflow Design

- Belt Driven

- Gear Drives

- VFD’s

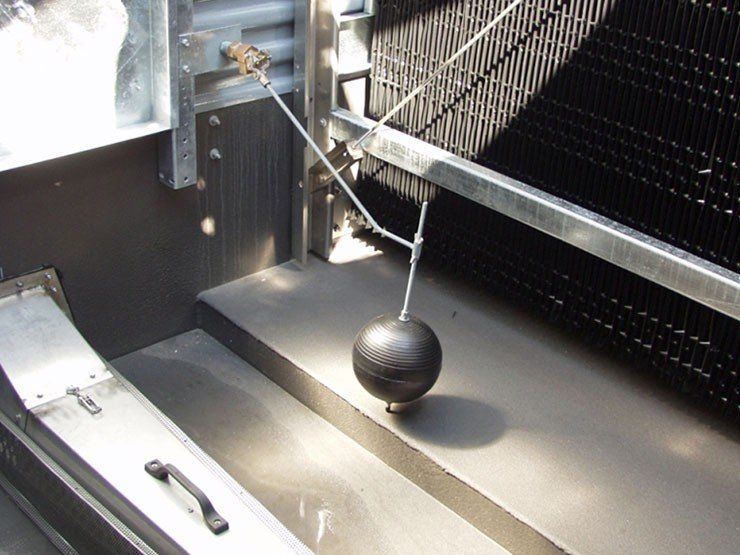

Filtration Systems

CT/HX evaluates and installs filtration systems into any cooling tower application. The filtration systems are designed to effectively control solids from building up in the cooling tower basins or remote sumps, thereby lowering maintenance and energy costs. Benefits from installing a filtration system on your cooling tower include:

- Reduced maintenance costs

- Reduced energy costs

- Reduced water consumption

- Reduced chemical usage

Request A Free Inspection

Inspections are available in all other regions for a small fee to cover travel expenses. Any inspection fees will be credited toward future work provided by CT/HX.